National Economy’s Plumbing Blog

Plumbing Articles from New Orleans, LA

Backflow Prevention Tips for NOLA Restaurants to Comply with Health Codes

Key Takeaways

- New Orleans restaurants face unique backflow prevention challenges due to the city’s flood-prone geography and strict health code requirements.

- Proper backflow prevention devices protect your customers from contaminated water and your business from health code violations that could lead to closure.

- Different areas of your restaurant require specific types of backflow preventers based on risk level, from simple air gaps to comprehensive RPZ assemblies.

- National Economy Plumbers provides expert backflow prevention services specifically tailored to the unique challenges restaurants face in NOLA.

- Annual testing and certification is mandatory for New Orleans restaurants, with documentation that must be submitted within 10 days via the SWBNO AquaResource Portal.

Why NOLA Restaurants Need Serious Backflow Prevention

Backflow isn’t just plumbing jargon, it’s a serious health hazard that can contaminate your restaurant’s water supply and sicken your customers. In the restaurant industry, where water safety directly impacts food preparation and sanitation, backflow prevention becomes especially critical. National Economy Plumbers has helped countless NOLA restaurants implement proper backflow prevention measures to protect both their customers and their business reputation.

Backflow occurs when contaminated water flows backward into your clean water supply. This can happen through back-pressure (when downstream pressure exceeds supply pressure) or back-siphonage (caused by negative pressure or vacuum in supply lines). In restaurant settings, the numerous cross-connections between potable water and potential contaminants, such as dishwashing chemicals, food preparation equipment, and floor drains, create multiple opportunities for dangerous backflow incidents.

Flood Risks That Make New Orleans Unique

New Orleans faces backflow challenges unlike anywhere else in the country. Our below-sea-level geography, frequent heavy rainfall, tropical storms, and hurricanes create perfect conditions for backflow incidents. During flooding events, contaminated floodwater can enter your restaurant’s plumbing system through various entry points, making robust backflow prevention essential rather than optional.

When city water pressure drops during storms or infrastructure failures, your restaurant’s plumbing system becomes particularly vulnerable. Without proper preventive measures, contaminated water from your drains, dishwashers, or even neighboring businesses can reverse direction and contaminate your clean water lines. This unique combination of geography and weather makes New Orleans restaurants particularly susceptible to backflow issues that most other cities rarely encounter.

Health Code Requirements You Can’t Ignore

The Louisiana Sanitary Code (Title 51) specifically mandates backflow prevention for restaurants. These aren’t just suggestions, rather they’re legal requirements enforced by local authorities like the Sewerage and Water Board of New Orleans (SWBNO). The code prescribes specific protection methods based on the degree of hazard, from low to high risk of contamination.

For food establishments, Part XXIII of Title 51 is particularly relevant, requiring approved backflow prevention methods for fixtures like sinks, dishwashers, and food preparation equipment. These regulations specify that water supply systems must be protected against backflow through proper air gaps or approved devices. Inspectors routinely check for these installations during health inspections, and violations can result in penalties or even restaurant closure.

“The potable water supply shall be protected from possible contamination sources within the premises. Approved backflow prevention devices must be installed on all fixtures and equipment where backflow conditions may exist.” – Louisiana Sanitary Code, Title 51

Common Violations That Shut Down Restaurants

Health inspectors across New Orleans frequently cite restaurants for backflow prevention violations that can lead to immediate closure. The most common infractions include missing backflow preventers on dish spray hoses (which often hang below sink flood rims), improperly installed devices, or failed annual testing certifications. These violations aren’t just paperwork problems, they represent real health risks to your customers.

Another frequent citation involves carbonated beverage systems without proper backflow prevention. When carbon dioxide dissolves in water, it creates carbonic acid that can corrode copper pipes and introduce copper into your drinking water. Hose bibbs (outdoor water spigots) without vacuum breakers and missing air gaps on food preparation sinks also rank among top violations that can temporarily shut down your restaurant operations.

Essential Backflow Prevention Devices for Your Restaurant

Selecting the right backflow prevention devices for your NOLA restaurant isn’t just about compliance, rather it’s about implementing a layered defense system against contamination risks. Each area of your restaurant presents different hazard levels, requiring specific prevention methods. The Louisiana Sanitary Code follows a hierarchical approach, starting with simpler solutions for low-risk areas and progressing to more complex devices for high-hazard zones.

Air Gaps: The Simplest Solution

Air gaps represent the most basic and effective form of backflow prevention, requiring no mechanical parts or maintenance. Simply put, an air gap is a physical separation between a water outlet and the flood level rim of a receiving vessel. In restaurants, this means ensuring faucets sit well above sink rims and that drainage hoses don’t hang below flood levels. Health inspectors specifically look for proper air gaps at three-compartment sinks, food prep sinks, and ice machine drains, as these are critical control points for preventing contamination.

The Louisiana Sanitary Code requires air gaps to be at least twice the diameter of the supply pipe, but never less than one inch. While this method is simple, it requires careful monitoring as staff often inadvertently defeat air gaps by attaching hoses or extensions that dangle below flood rims, creating an immediate cross-connection hazard. Regular staff training about maintaining proper air gaps should be part of your restaurant’s food safety program.

Vacuum Breakers for Low-Risk Areas

Atmospheric vacuum breakers (AVBs) and pressure vacuum breakers (PVBs) provide essential protection in low to moderate risk areas of your restaurant. These devices prevent back-siphonage by allowing air to enter the system when pressure drops. Vacuum breakers are ideal for hose bibbs, service sinks, and some dishwashing applications where the risk of chemical contamination exists but isn’t severe.

For NOLA restaurants, installing vacuum breakers on outdoor hose connections is particularly important due to flooding risks. When floodwaters rise, unprotected hose bibbs become direct pathways for contaminated water to enter your building’s plumbing system. These relatively inexpensive devices ($20-50 each) represent one of the most cost-effective backflow prevention measures available to restaurant owners.

Double Check Valves for Moderate Hazards

Double Check Valve Assemblies (DCVAs) feature two independently operating check valves that prevent both back-pressure and back-siphonage. These devices are appropriate for moderate hazard applications in restaurants, including water lines serving kitchen equipment without chemical additives. The dual-check design provides redundant protection, ensuring safety even if one valve fails.

DCVAs require annual testing and occasional maintenance, but they offer reliable protection without the complexity of RPZ assemblies. For NOLA restaurants, these devices work well for connections to ice machines, coffee brewers, and similar equipment. However, they’re not appropriate for high-hazard applications where toxic chemicals or biological contaminants are present.

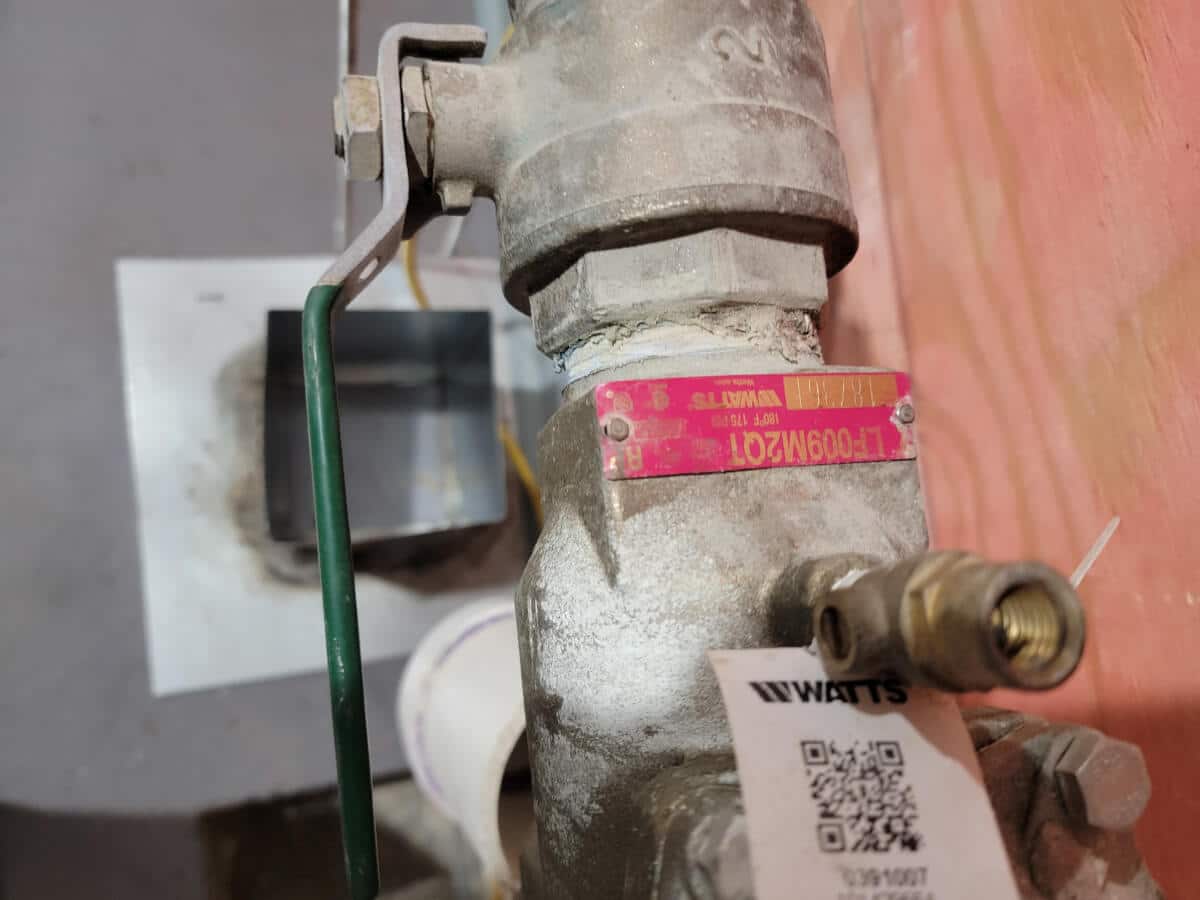

Reduced Pressure Zone (RPZ) Assemblies for High-Risk Zones

For maximum protection in high-hazard areas, Reduced Pressure Zone (RPZ) assemblies are the gold standard and often required by code. These sophisticated devices combine two independently acting check valves with a hydraulically operating pressure differential relief valve. RPZs protect against both back-siphonage and back-pressure while providing a fail-safe mechanism that discharges water if either check valve fails.

In New Orleans restaurants, RPZ assemblies are essential for protecting water lines connected to dish machines using chemical sanitizers, water lines feeding boilers with chemical additives, and any connections where serious contaminants could enter the water supply. While more expensive ($200-800 depending on size) and requiring regular professional maintenance, these devices provide peace of mind for the most critical applications in your restaurant.

Choosing the Right Device for Each Area

The SWBNO requires different levels of protection based on the degree of hazard present. Low hazards typically need atmospheric vacuum breakers or double check valves, while high hazards require RPZ assemblies or properly maintained air gaps. The key to compliance is assessing each water-using fixture or piece of equipment individually to determine its contamination potential.

Device Comparison

Critical Installation Points in Your Kitchen

Sinks and Dishwashers: Primary Risk Areas

Commercial dishwashers and prep sinks represent some of the highest backflow risks in your restaurant. These fixtures use a combination of potable water, chemicals, and potentially contaminated wastewater. For commercial dishwashers, the Louisiana Sanitary Code requires either an approved air gap or an RPZ assembly, especially for units using chemical sanitizers. The corrosive nature of these chemicals makes them particularly dangerous if they backflow into your potable water supply.

Prep sinks and three-compartment wash sinks must maintain proper air gaps on faucets and spray nozzles. A common violation occurs when staff attach hoses to faucets, allowing the hose end to dangle below the flood rim. This creates an immediate cross-connection that can introduce contaminants during pressure fluctuations. Installing proper air gaps and training staff to maintain them is essential for both compliance and safety.

Beverage Machines and Ice Makers

Carbonated beverage systems pose unique backflow hazards due to the carbonic acid created when CO2 dissolves in water. This acidic solution can corrode copper pipes, introducing copper contamination into drinking water. The Louisiana Sanitary Code specifically requires specialized backflow preventers for carbonated beverage dispensers, either a dedicated RPZ assembly or a specially designed backflow preventer with internal stainless steel components resistant to carbonic acid corrosion.

Ice machines require their own backflow preventive measures, as they combine water connections with drainage systems that can harbor bacteria. The water supply line to your ice machine should be protected by at least a double check valve assembly, while the drainage line must maintain a proper air gap to prevent wastewater from being siphoned back into the machine. In flood-prone New Orleans, elevated ice machines with proper drainage systems provide additional protection against contamination during flooding events.

Coffee machines, especially those connected directly to water lines, need appropriate backflow prevention based on whether they use chemicals or cleaning solutions. For standard coffee brewers without chemical additives, a double check valve assembly typically suffices. However, more sophisticated machines with automatic cleaning cycles or chemical additives may require RPZ protection.

Mop Sinks and Floor Drains

Mop sinks and floor drains present significant cross-connection hazards in restaurant environments. These fixtures regularly come into contact with cleaning chemicals, food waste, and potentially contaminated water. Every mop sink faucet should be equipped with an atmospheric vacuum breaker to prevent cleaning solutions from being siphoned back into your potable water system during pressure drops.

Floor drains in NOLA restaurants require special attention due to flooding risks. When floodwaters rise, these drains can become entry points for contaminated water to enter your establishment. Backwater valves on floor drains can prevent sewage backups during flooding, while proper grading away from your building helps minimize water intrusion. Regular cleaning and maintenance of floor drains also prevents blockages that could exacerbate backflow issues during heavy rainfall events.

Water Heaters and Boilers

Water heating equipment presents unique backflow challenges, especially in commercial kitchens. Boilers and water heaters often contain chemicals to prevent scale buildup and corrosion. Without proper backflow preventive measures, these chemicals can be drawn back into your potable water supply during pressure fluctuations.

NOLA restaurants should install RPZ assemblies on water lines feeding boilers or water heaters that use chemical additives. Additionally, thermal expansion tanks are necessary to accommodate water expansion that occurs during heating cycles. These tanks prevent excessive pressure buildup that could overcome backflow preventers and create back-pressure situations. Annual inspection of these systems is essential, as thermal expansion issues often develop gradually over time.

Monthly Maintenance Checklist

Visual Inspections Anyone Can Do

Implementing a monthly visual inspection program helps catch potential backflow issues before they become serious problems. Train your management team to look for signs of trouble, including leaking backflow preventers, damaged air gaps, or hoses hanging below flood rims. Document these inspections as part of your overall food safety program to demonstrate due diligence to health inspectors.

A simple monthly checklist should include verifying that spray hoses are properly stored above sink flood rims, checking that vacuum breakers on hose bibbs haven’t been removed, and confirming that drainage hoses from ice machines and beverage equipment maintain proper air gaps. Also inspect RPZ assemblies for signs of discharge from relief valves, which indicates potential failure requiring immediate professional attention.

- Check all hose connections for proper air gaps and storage above flood rims

- Verify vacuum breakers on hose bibbs are intact and not leaking

- Inspect RPZ relief valve discharge ports for signs of water or leakage

- Confirm ice machine and beverage equipment drain lines maintain proper air gaps

- Check under sinks for any unauthorized modifications to plumbing that could create cross-connections

Cleaning Procedures for Prevention Devices

Regular cleaning of backflow prevention devices extends their lifespan and ensures proper operation. Simple devices like vacuum breakers benefit from occasional external cleaning to remove grease, dust, and debris that could affect their function. For air gaps, regular cleaning of the surrounding areas prevents buildup that could bridge the gap and create a cross-connection.

RPZ assemblies and double check valves should be kept clean externally, with particular attention to relief valve discharge ports. Never block these ports, as they provide the critical fail-safe function that makes these devices effective. Schedule professional cleaning of internal components during your annual certification testing to remove mineral buildup and ensure smooth operation of all moving parts.

When to Call a Professional

While visual inspections and basic cleaning can be handled by trained staff, certain situations require immediate professional intervention. Any sign of water discharging from an RPZ relief valve indicates a potential failure and requires expert evaluation. Likewise, leaking or damaged backflow preventers should be addressed by certified professionals to ensure proper repair or replacement.

If you notice unusual water quality issues, like discolored water, unusual taste or odor, or sediment in your water supply, contact a licensed plumber specializing in backflow device repair immediately. These symptoms could indicate existing backflow contamination that requires thorough investigation and remediation. National Economy Plumbers specializes in diagnosing and resolving these complex backflow issues in New Orleans restaurants.

Testing and Certification Requirements

Annual Testing Timeline

The Sewerage and Water Board of New Orleans (SWBNO) requires annual testing of all backflow prevention assemblies by certified testers. This isn’t optional, it’s a mandatory requirement to perform annual testing of backflow devices for continuing restaurant operation. Plan your testing schedule to avoid your busiest seasons, as water service may need to be temporarily interrupted during testing procedures.

Test results must be submitted to SWBNO within 10 days of completion via their AquaResource Portal. Many restaurant owners don’t realize that delayed submission can result in penalties even if the devices pass testing. Mark your calendar with testing dates and submission deadlines to ensure continuous compliance. Failure to maintain current certifications can result in citations during health inspections or even service interruptions.

Finding Certified Testers in New Orleans

Only backflow prevention assembly testers with current SWBNO certification can perform valid testing for your restaurant. The Sewerage and Water Board maintains an official list of approved testers, which you can obtain through their website or by contacting their Cross-Connection Control department. Always verify a tester’s current certification before scheduling service.

When selecting a tester, look for someone with specific restaurant experience who understands the unique challenges of food service environments. Ask whether they can provide both testing and any necessary repairs during the same visit to minimize disruption to your operations. Many restaurants establish ongoing relationships with reliable testers who become familiar with their specific systems and requirements.

Documentation You Must Keep On Hand

Proper documentation is essential for demonstrating compliance during health inspections. Maintain an organized file containing test reports, repair records, and installation certifications for all backflow prevention devices in your restaurant. These records should be readily accessible to both management and inspectors.

Beyond test reports, keep documentation of any backflow preventer repairs, replacements, or new installations. For RPZ assemblies, maintain records of the specific model, serial number, installation date, and location. Health inspectors often request these documents during routine inspections, and having them readily available demonstrates your commitment to water safety and regulatory compliance.

Emergency Protocols for Flooding Events

New Orleans restaurants must prepare for flooding events that can compromise backflow preventer systems. Developing clear emergency protocols ensures your staff knows exactly what steps to take before, during, and after flooding to protect water safety. These procedures should be documented in your emergency response plan and reviewed regularly with all managers.

The primary goal during flooding is preventing contaminated water from entering your potable water system through compromised backflow preventers or cross-connections. This requires both preventive measures before storms and specific actions during and after flooding events. Proper preparation can significantly reduce the risk of contamination and minimize recovery time after the waters recede.

Before the Storm Hits

When severe weather threatens, implement proactive measures to protect your backflow prevention systems. If possible, close the main water supply valve to your building to create a physical barrier against contamination. Remove or elevate any portable equipment with water connections, and secure outdoor backflow assemblies against potential flood damage.

Documenting your water system with photos before an emergency provides valuable reference points for post-storm assessment. Pay particular attention to RPZ assemblies, noting their condition and settings. If evacuation is necessary, consider shutting down water-using equipment and, if time permits, draining pipes to minimize contamination risk.

During Flooding or Water Pressure Issues

During flooding or when water service is interrupted, implement strict “water unsafe” protocols throughout your restaurant. Post notices at all water outlets warning against consumption, and use bottled water for any necessary operations. Never attempt to operate water-using equipment during flooding or low-pressure events, as this creates ideal conditions for backflow contamination.

Monitor city alerts for boil water advisories, which indicate possible contamination of the municipal water supply. If your restaurant experiences flooding or you notice water pressure issues, assume your backflow preventers may be compromised and treat all water as potentially contaminated until professional testing confirms otherwise.

Post-Flood Inspection Requirements

After floodwaters recede, comprehensive inspection of all backflow prevention devices is mandatory before resuming normal operations. Contact a certified backflow tester immediately to schedule emergency testing of all devices that may have been submerged or affected by pressure fluctuations. These inspections cannot be postponed or overlooked, as flooding events can damage or compromise even properly installed preventers.

Beyond backflow devices, your entire water system requires thorough assessment after flooding. This includes flushing water lines, sanitizing fixtures, and testing water quality before resuming food service operations. Document all post-flood inspections, repairs, and water quality tests for health department review, as these records may be requested to authorize reopening after significant flooding events.

Take Action Today to Protect Your Restaurant and Customers

Implementing proper backflow prevention isn’t just about code compliance—it’s about protecting your customers, your reputation, and your business continuity in New Orleans’ challenging environment. Schedule a comprehensive backflow prevention assessment with National Economy Plumbers today to identify vulnerabilities before they lead to contamination incidents or health code violations.

Protect your NOLA restaurant today. Contact National Economy Plumbers for expert backflow prevention and annual certification. Schedule now!

Requirements current as of 2026. Backflow regulations and SWBNO processes can evolve, always verify the latest details directly with the Sewerage and Water Board of New Orleans (SWBNO) at swbno.org.

Frequently Asked Questions (FAQs)

Restaurant owners in New Orleans often have questions about backflow prevention requirements and best practices. Below are answers to some of the most common inquiries we receive at National Economy Plumbers regarding backflow prevention for NOLA restaurants.

These responses reflect current regulations from the Louisiana Sanitary Code and Sewerage and Water Board of New Orleans requirements. However, regulations can change, so always verify current requirements with authorities when planning new installations or modifications.

How much does backflow prevention installation typically cost for a NOLA restaurant?

Installation costs for NOLA restaurants vary by device: $150–300 for simple vacuum breakers, $500–1,000 for double check valves, and $800–2,000 for RPZ assemblies (installed). Phased implementation targeting high-risk areas first helps manage budgets effectively.

Can I test my own backflow prevention devices or must I hire someone?

No, restaurant owners or staff cannot perform official backflow testing in New Orleans. Annual certification must be done by an SWBNO-certified tester with specialized equipment and training; only visual inspections can be handled in-house.

What penalties might I face for backflow prevention violations?

Penalties for backflow violations in NOLA restaurants include fines of $250–$1,000 per issue, temporary closure, permit suspension, water service disconnection, and potential liability for customer illnesses if codes are violated.

How often do I need to replace backflow prevention devices?

Most quality backflow preventers last 5–10 years with proper maintenance, though RPZ assemblies may need parts replaced more often. Your certified tester can recommend timing based on annual inspections and water conditions.

Will my insurance cover damages caused by backflow incidents?

Standard business insurance often excludes coverage for backflow damages from code violations or poor maintenance. Specialized riders may apply if you prove ongoing compliance and regular testing, review your policy and consider add-ons.

Request a Quote Now

Serving New Orleans, Metairie, Kenner, Merrero, Chalmette & Terrytown LA

FREE ESTIMATES

national economy plumbers

Full Service Plumbing New Orleans, Louisiana

National Economy Plumbers

7204 Washington Ave.

New Orleans, LA 70125

(504) 322-3950

or Send Us an Email Here.

© 2012-2024 NationalEconomyPlumber.com

– All rights reserved. –

Information on this website may not be re-used without prior written consent from National Economy Plumbers.

HOURS & LICENSE INFO

Monday-Friday: 8:00am to 5:00pm

Saturday-Sunday: Client Emergencies Only

Louisiana Licensed, Bonded, Insured

Master Plumbers License LA LMP 214

Master Natural Gas Fitters LA LMNGF 8026

Orleans Plumbing #40 / Gas #03LGA11246

Jefferson Plumbing #408 / Gas #761